The GLT chassis tipper comes in a range of sizes to suit your needs. Paired up with a lead unit or a tag, you will have the ability to haul a range of goods efficiently and achieve greater profit margins.

A standard tri axle 33′ grain spec GLT chassis tipper will tare in at around 6.4 tonnes. Our selection of materials, designs and methods of fabrication will give you an industry leading low tare trailer with exceptional strength.

The highest quality parts are sourced to manufacture each GLT unit. All nuts, bolts and washers are stainless steel. Grain scrapers, shovels, brooms and grain chutes are equipped as standard. Every trailer is professionally detailed before it is delivered to the customer.

All GLT trailers are laser wheel aligned prior to delivery. GLT chassis tippers are available in tandem, tri or quad axle configurations. We have a large range of options to customise your new chassis tipper. See below for some of our most popular options.

Tandem axle

| Detail: | Measurement: |

|---|---|

| Length: | 19’8″ to 28′ |

| Height: | 4′ to 8’6″ |

| Capacity: | 17 to 58 cubic metres |

| Tare Weight: | 4.5 to 5.8 tonnes |

Tri axle

| Detail: | Measurement: |

|---|---|

| Length: | 27’11” to 36′ |

| Height: | 4′ to 8’6′ |

| Capacity: | 25 to 80 cubic metres |

| Tare Weight: | 5.6 to 7.2 tonnes |

All GLT aluminium bodies are fabricated from European sourced marine grade aluminium plate. Floor and wall sheet thicknesses can be customised to suit the application.

Straight Body – This standard body type is a strong, cost effective and a light weight option. Choose from two body widths: Narrow – 2,330mm or Wide (standard) – 2,480mm.

Drop Deck – The drop in the floor will increase the trailer’s capacity by 4-8 cubic meters depending on the trailer length. Tare weight will be increased by round 70kgs.

Wedge – This option will give you a similar capacity increase as the drop deck. Tare weight increase will also be similar to the drop deck style body.

Plate – 4mm to 12mm thickness. Choose from either mill finish, mill bright (polished), painted or vinyl.

Standard Lower Curve – The GLT lower curve is an exclusive extrusion. The side sheet and floor sheet slot into the extrusion before they are hand welded into place.

Pressed Sides – GLT can remove the lower curve and press the side sheet to meet the floor sheet. This will reduce the tare weight by around 70kg. It also increases the strength of the tubs making it an ideal option for carrying liquid based goods.

Plank – GLT custom extruded planks. These are ideal for maximum height bodies as they reduce the amount of side wall bulge. This option will increase the trailer tare weight by around 80kg depending on length and height.

Standard Flat Front Sheet – This is our standard front sheet which is 5mm thick with a polished finish. Other thicknesses and finishes are available.

Rounded Front Sheet – This option is ideal for carrying liquid based products. The front sheet is specially rolled before being welded into the place. As liquids move forward when decelerating, the shape of the front sheet reduces the liquid’s impact. We recommend a thickness of 6mm to add stiffness to the front sheet which reduces fatigue.

All our chassis are fabricated from 700-grade mechanical steel with quenched and tempered skid plates. Minor amounts of 350 and 250 grade steel are used for small profile gussets.

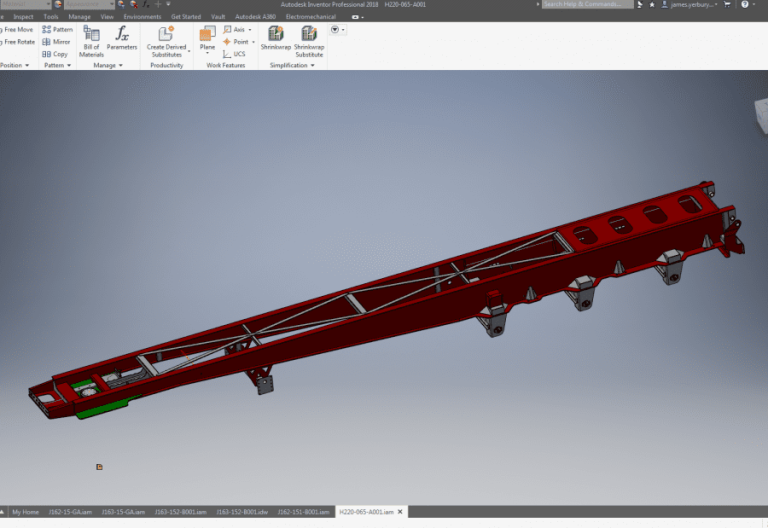

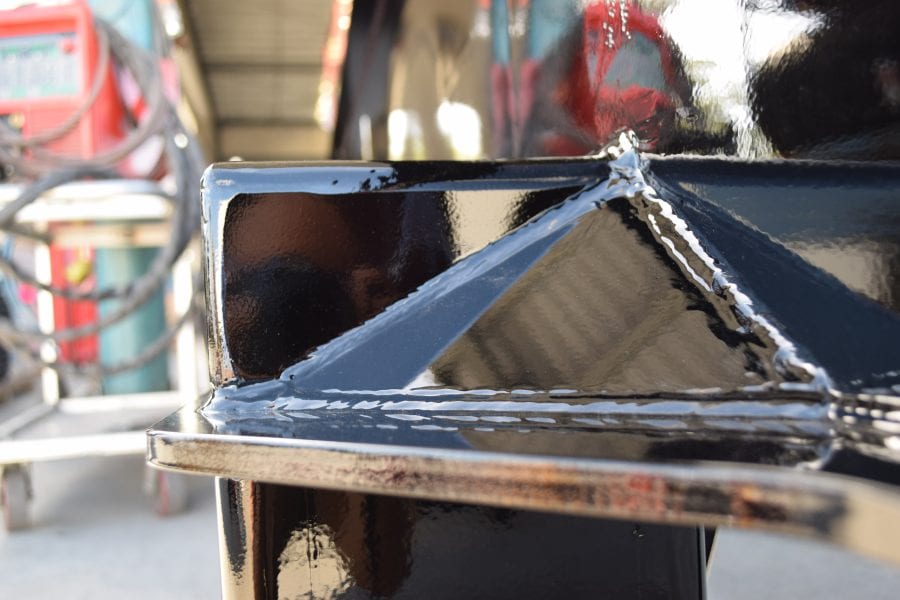

Each chassis is 3D modelled and laser cut. Our steel fabrication team are highly skilled qualified tradesmen. Miller digital pulse welders are used to lay a clean weld.

All edges on flanges are sanded and polished to reduce the chances of cracking and to help paint adhere to the steel.

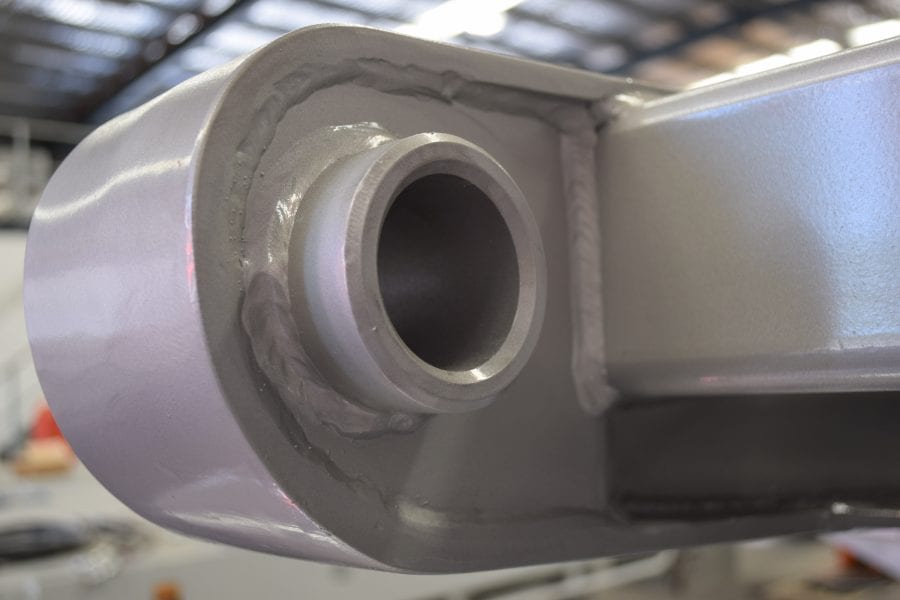

Our pivots use a superior through design which greatly increases the strength of the pivot area. A 50mm pivot pin is slotted through a welded connection, making it exceptional strong.

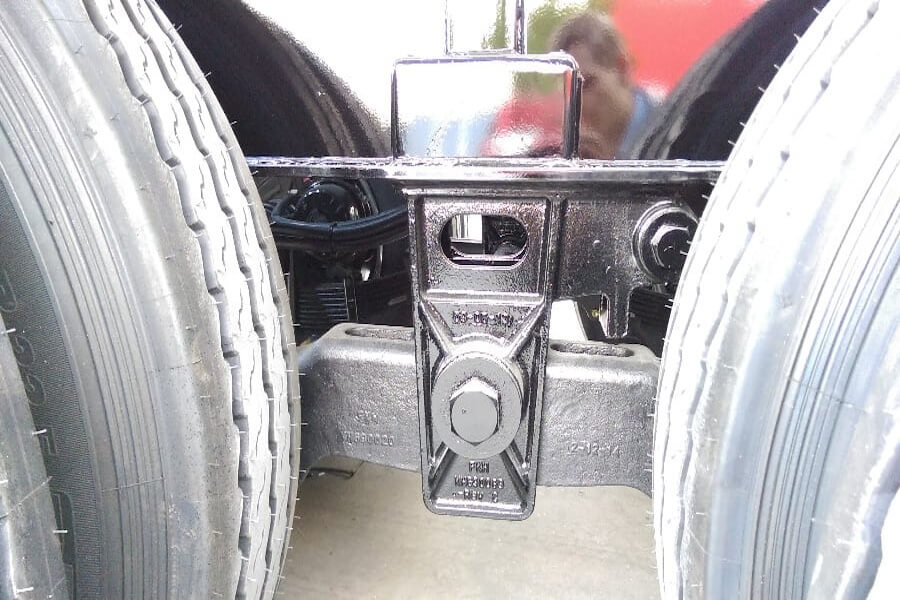

GLT chassis are optimised for Hendrickson Intraax airbag suspension and axles. Other brands such as BPW, SAF and K-Hitch can be optioned. Subtle design changes are made to the chassis to accommodate these different suspension brands ride characteristics.

GLT trailers are designed to handle the harsh Australian conditions. The correct suspension and axle selection is one of the most important factors in the trailers’ ability to survive our unique roads.

GLT chassis are optimised for Hendrickson INTRAAX air bag suspension and Hendrickson axles. Other brands such as BPW, SAF and K-Hitch can also be equipped if requested. GLT is an authorised Hendrickson dealer which allows us to offer greater after-sales support.

Air bag suspension offers better ride quality, low tare weight and simplified ways of reading load weights. The prefered brands which we supply have passed our field testing protocol and have excellent after sales support. All trailers with air bag suspension are equipped with ball valve taps to isolate individual bags. These taps will allow you to shut off an air bag if it has an issue.

Mechanical spring suspension can be fitted to most GLT trailers. K-Hitch KHDO/KHU and FW88 are our preferred suspension models.

By far our most popular option. The tarp rolls up neat and tidy out of the way when loading. When unrolled, the tarp offers a high level of cover to protect your load. Compared to the QLD style tarp, the roll over is easier for the operator to use, reducing OH&S risks. Side drop is 300mm standard and can be increased to 600mm. A full range of colours available. Razor electronic tarp upgrade available on this tarp.

If you want the most water proof tarp option, tick this option. Tarps come standard with 300mm long flaps front and rear which are pull down tight to seal the front and rear of the tub. The side drop is standard at 600mm. This gives you a bit of extra room to roll over the heaped loads while still getting a tight seal along the side of the tub. A full range of colours are available.

These tarps retract forward to allow loading. The rear part of the tarp has a flap end which is pulled down tight to seal the rear of the trailer once loaded. The tarp supports can range from 200mm to 350mm high. Retractable tarps are not waterproof and leaking can occur. A full range of colours are available.

Our standard light spacing interval is 1300-1500mm. If you want more light bling then we can go as close as 300mm between lights. We also offer lights at the top of the side sheets at matching intervals.

Tailgate pivots from the top only.

Tailgate can pivot from either the top of the side. A parrot break and pivot bold is needed to allow the 2 way system to work.

This door style uses container style locks and stainless steel hinges. The doors can be fixed open with latches.

Our most popular type of hinge. This hinge sits outside of the body.

This hinge allows for the rear door to close flush. Some people say that this hinge type is pretty good looking, too.

The rear of the tailgate has the internal support posts exposed. This style door is our lightest door.

This style gives the door a clean finish. There is a weight penalty of around 50-80kgs. The inside of the door is still a flush finish just like the standard tailgate.

The fingers and assembly are fabricated from stainless steel. You can choose from either manually operated or air-operated. Air-operated 4-finger locks have a single air ram, which provides locking force.

The fingers and assembly are fabricated from stainless steel. You can choose from either manually operated or air-operated. Air operated 7 finger locks are 2 air rams which provides the locking force.

Select from either single or double manual grain locks. Our grain lock handles are fabricated from stainless steel. The wear pads are mounted to the tailgate and made from stainless steel.

We offer 2 different types of air grain locks. The upright and the horizontal verison. Both options give exceptional sealing pressure. Air grain locks are syncronised with the air finger locks - all off the one push/pull switch.

Recommend for operators wanting to cart products such as hides. These locks are manually operated and provide excellent sealing pressure. The door plug seals the grain door water tight.

This option is suited to tailgates where clearance with the ground or other trailers is an issue. We can do a single or a double split. The split is controlled by a single or twin air ram.

A popular option. The vinyl is applied in 1400mm wide drops with a slight overlap. Each drop can be replaced if they get damaged, making it less expensive to maintain compared to paint. Select from a large range of colour options.

Dress up your radius guards with chrome dress strips. These look great and finish off the guard area nicely.

Another well-known EBS unit popular with our clients. This unit offers stability control and EBS braking. Knorr Bremse offer excellent technical aftersales support.

If safety is high on your list when operating, then you need to consider the Wabco EBS system. This electrically-controlled braking system helps to reduce the risk of serious accidents.

This is a must-have option for our RediTip range of trailers. As the trailer approaches jack knife, the EBS system will activate the brakes to save your trailers from damage.

These special valves recognise the difference in axle load and adjust braking force.

This special lining will give the floor sheet extra protection as well as provide a slick surface to reduce friction. This style of lining will increase the chances of contamination if you are hauling different loads.

Choose from either aluminium or steel. We have a range of thicknesses to suit your needs. Wear plate can be added to the floor or walls.

Are you needing to protect your side sheets from abrasive loads? Rock sheeting will extend the life of your trailer. We use 4mm pressed plate and can be added to the sides, front sheet and door.

Contact our team to discuss your customised trailer requirements to receive tailored advice and a quote.

Phone

1300 731 442